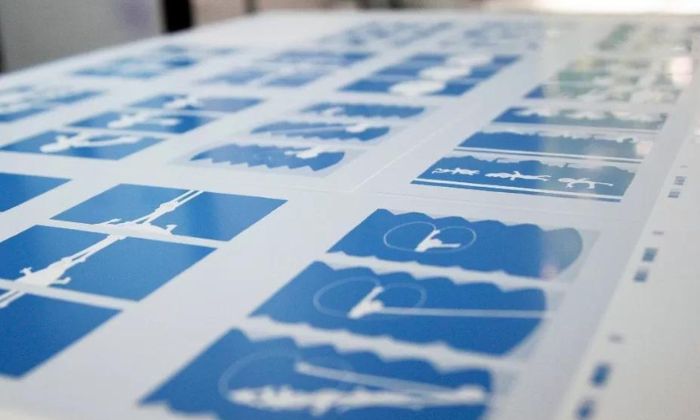

Printing Plates

Unveiling the Role of Printing Plates in the Printing Process

Printing plates are integral components in the printing process, serving as the foundation for transferring images onto various surfaces. These plates play a crucial role in offset printing, flexography, and other printing methods. This article will delve into the significance of printing plates, their types, uses, and importance in the realm of printing technology.

Understanding Printing Plates

Printing plates are thin, flat sheets typically made of metal, plastic, or rubber, carrying the image or text to be printed. They act as the intermediary surface that transfers ink onto the substrate, whether it's paper, cardboard, or other materials. The plates hold the image areas to be printed, while the non-image areas repel ink.

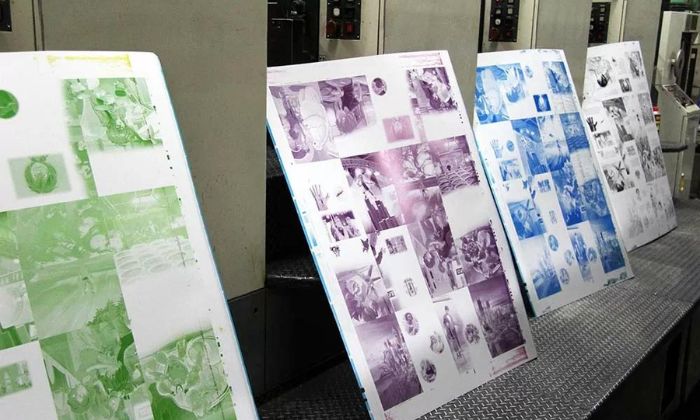

Types of Printing Plates

Offset Printing Plates: Made of aluminum, these plates transfer ink from a roller to a rubber blanket and then to the printing surface.

Flexographic Printing Plates: Typically made of rubber or photopolymer, these plates are flexible and used in flexible packaging and label printing.

Gravure Printing Plates: Made of copper or steel, these plates feature recessed cells that hold ink and are commonly used for high-quality printing, such as magazines and catalogs.

Lithographic Plates: Used in lithography, these plates have an image area that repels water and attracts ink, while non-image areas repel ink and attract water.

The Role of Printing Plates

Image Transfer: Printing plates transfer the image or text onto the substrate during the printing process.

Ink Repellence: Non-image areas on the plates repel ink, ensuring only the intended areas receive ink for printing.

Precision and Detail: Quality plates enable high-resolution and accurate reproduction of images and text.

Consistency in Printing: Well-maintained plates ensure consistent print quality throughout the print run.

Adaptability: Different plate types suit various printing methods and substrates, providing versatility in printing applications.

Importance of Printing Plates in the Printing Industry

Quality Output: Well-prepared plates are crucial for achieving high-quality, crisp prints with accurate colors and details.

Efficiency: Properly maintained plates reduce downtime, allowing for smoother and more efficient printing operations.

Cost-Effectiveness: Quality plates contribute to reduced waste, minimizing reprints and material usage.

Versatility: Different types of plates accommodate various printing needs, from newspapers to packaging materials.

Technological Advancements: Ongoing advancements in plate technology improve durability, precision, and environmental impact.

Conclusion

Printing plates serve as the backbone of the printing process, facilitating the accurate reproduction of images and text onto various substrates. Their role in ensuring quality output, efficiency, and versatility in printing technology underscores their significance in the printing industry.

In conclusion, printing plates play a pivotal role in the printing industry, serving as essential components in transferring images and text onto surfaces. Their types, precision, and adaptability contribute to achieving high-quality prints and efficient printing processes across various applications and printing methods.